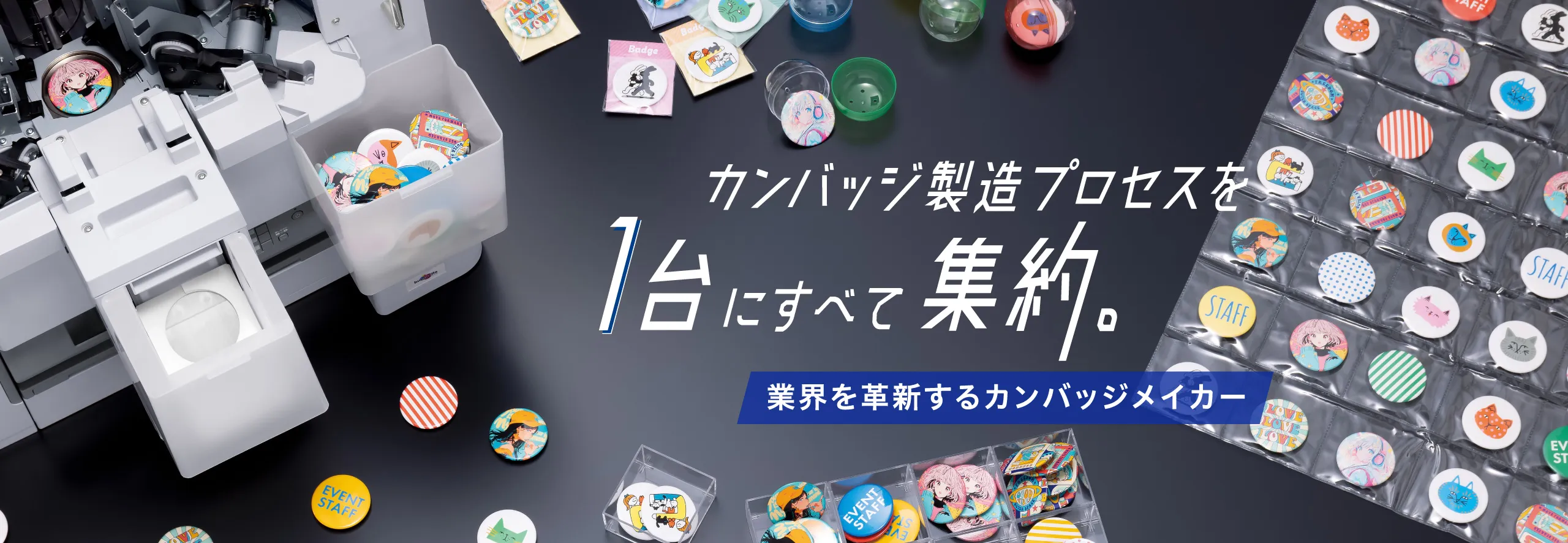

Brother Can Badge Maker

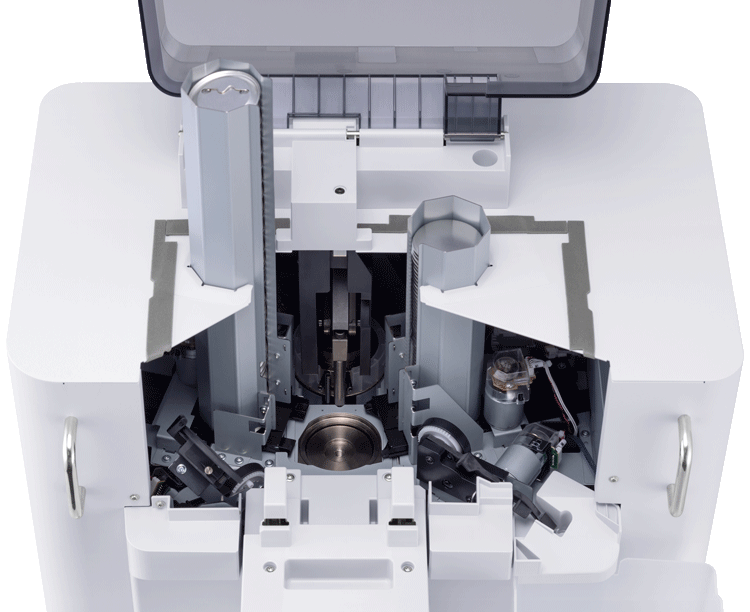

Fully Automatic Badge Creation

Printing, cutting, and crimping processes are completed in a single device. The operator only needs to send print instructions from the PC and replenish consumables, making it possible to operate the machine single-handedly.

Efficient and Easy Operation

Simply print from the dedicated Windows-compatible application, eliminating the need for RIP software or specialized software. Various settings can be easily selected from the included software "CanbadgeMachineController".

Badge Parts Setting

The back parts with pins come with a dedicated jig for setting, allowing parts to be filled at the same angle. Back parts and shells can be set 25 at a time, with a maximum capacity of 50 pieces.

Original Back Parts

By utilizing the attachment on the pin, it's possible to stand and display the badge. When the attachment is in place, the pin cannot be easily removed, serving as a safety measure.

High-Capacity Ink

Supports high-capacity ink cartridges with approximately 5,000 color prints and 6,000 black prints.

Significantly reduces ink replacement hassle, and cartridge-based design makes replacement easy.

*Based on printing conditions for A4 plain paper.

Significantly reduces ink replacement hassle, and cartridge-based design makes replacement easy.

*Based on printing conditions for A4 plain paper.

Sub Tank

Adopts a system that transfers ink from the cartridge to the main unit's sub tank.

Enables approximately 200 prints even after the cartridge is empty, providing peace of mind if you forget to purchase ink.

*Based on printing conditions for A4 plain paper.

*Approximate number of prints based on ISO/IEC24711 standard. May vary depending on usage conditions.

![Brother Can Badge Maker [Body] Brother Can Badge Maker [Body]](images/categories/BBFA057M0000.jpg)

![Brother 57mm Can Badge Maker [Body] Brother 57mm Can Badge Maker [Body]](images/BBFA057M0000.jpg)

![Brother Backparts for 57mm Can Badge Maker [1000 pcs] Brother Backparts for 57mm Can Badge Maker [1000 pcs]](images/BB057BPZ01000.jpg)

![Brother Shell for 57mm Can Badge Maker [1000 pcs] Brother Shell for 57mm Can Badge Maker [1000 pcs]](images/BB057SH01000.jpg)

![Brother Base Film for 57mm Can Badge Maker [1000 pcs] Brother Base Film for 57mm Can Badge Maker [1000 pcs]](images/BB057BF01000.jpg)